Innovative technology meets with powerful performance

CHINAPLAS2024

4.23-4.26

National Exhibition and Convention Center (NECC), Hongqiao, Shanghai

We sincerely invite you to visit us

Tederic Booth: 5.1C52

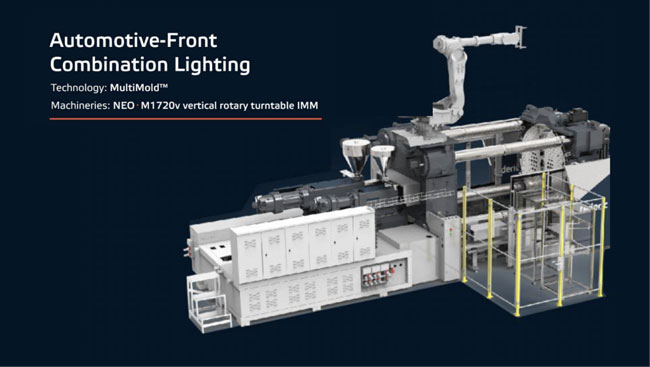

Front Combination Lighting Injection Molding Application

NEO•M1720v vertical rotary turntable IMM

|

Product: Front Combination Lighting

Cavity Qty: 2

Material: PC+PC

Single Weight: 517g

Time Cycle: 170s

Technology: MultiMold™ Multi-color Master Technology |

01

Featuring Tederic MultiMold™ technology, Free layout of injection units. The modular platform structure can form up to more than 30 combinations. Diversified cost-effective solutions

02

Integrated low-speed high pressure, and two-color process molding meet the front combination lamp's ultra-high light distribution requirements.

03

Turntable with brake servo drive, 23-bit high precision absolute encoder. Rotary control accuracy up to 0.01°; The turntable spins fast

180° Rotation time is only 3.6s

04

The turntable adopts a high-torque tube structure. Cold and hot isolation.Durability and low maintenance costs

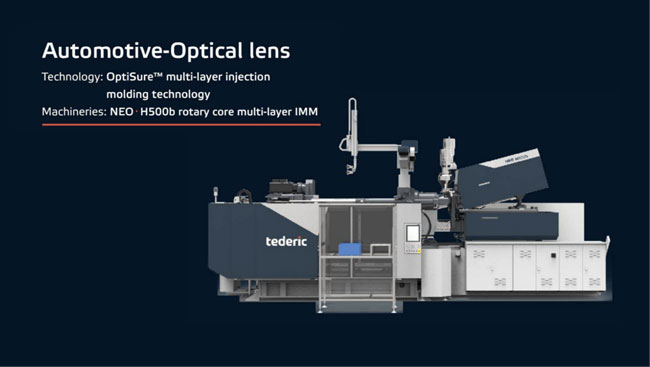

OptiSure™ Multi-layer Thick-wall Lens Injection Molding Application

NEO•H500b rotary core multi-layer IMM

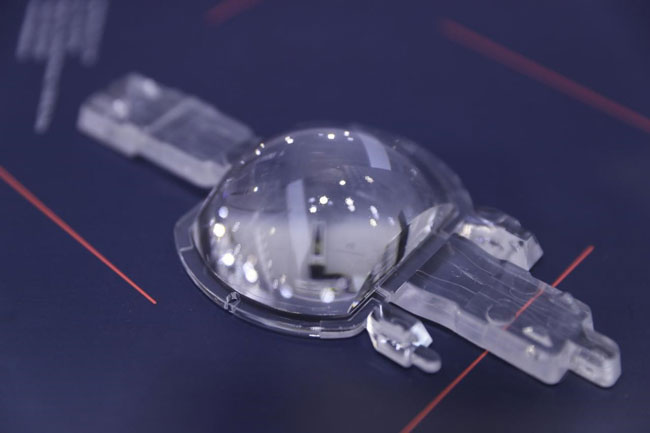

Product: Optical lens

Cavity Qty: 4

Material: PMMASingle

Weight: 82.7g

Time Cycle: 220s

Technology: OptiSure™ Multi-layer Injection Molding Technology

|

01

Layered injection molding and external cooling. Utilizing OptiSure™ multi-layer injection molding technology. Increase optical lens production efficiency by 30%

02

Flexible multi-stage injection molding technology. During the production cycle, injection and charging are carried out at the same time. Solve the yellowing problem caused by the long retention time of raw materials in the barrel. Bring greater design freedom for mold development.

03

With an electric shot. The fluctuation of injection speed is controlled within 0.2mm/s. Effectively avoid the flow marks and stress inequality defects of thick-walled optical parts.

04

Electro-hydraulic technology is adopted. Production energy consumption is less than 0.32 kWh/kg.

2024 Tederic OPEN HOUSE

During the exhibition, Tederic International Center will hold an OPEN HOUSE at the same time. We look forward to your visit!

Time:4.22-4.26

Location: Tederic Global Headquarter

No. 417, Yinhai Street, Hangzhou, Zhejiang, China

* During CHINAPLAS, buses will depart daily from the exhibition hall to Tederic Global Headquarters and factory, returning to the exhibition hall in the evening. Please contact a Tederic representative or register by scanning the code below to book this tour.

Scan the QR code

Register for the 2024 Tederic open house