As a renowned plastic processing industry exhibition in Central Europe, PLASTPOL has become a barometer for the local plastic and rubber industry, attracting representatives from nearly a thousand companies worldwide.

At this year's exhibition, Tederic unveiled its latest energy-efficient injection molding equipment and intelligent production solutions, showcasing outstanding innovation and technological prowess in the plastics industry. The on-site response was enthusiastic, further enhancing the brand’s influence.

On the first day of the exhibition, May 21, at booth G-14, Tederic's Electric IMM showcased high-speed thin-wall packaging intelligent injection molding solutions, garnering widespread attention and receiving unanimous praise from visitors.

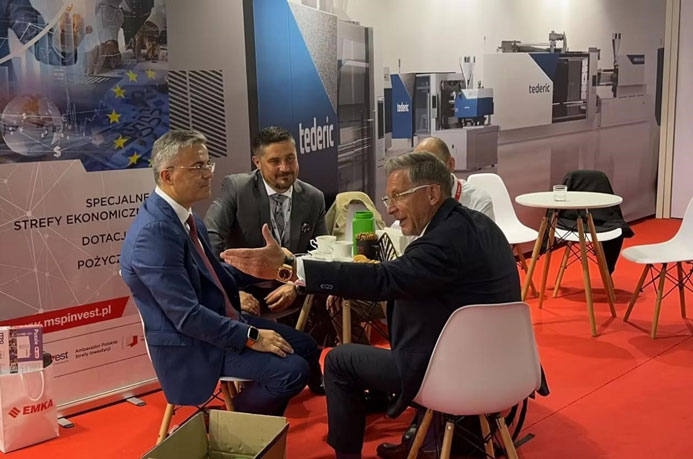

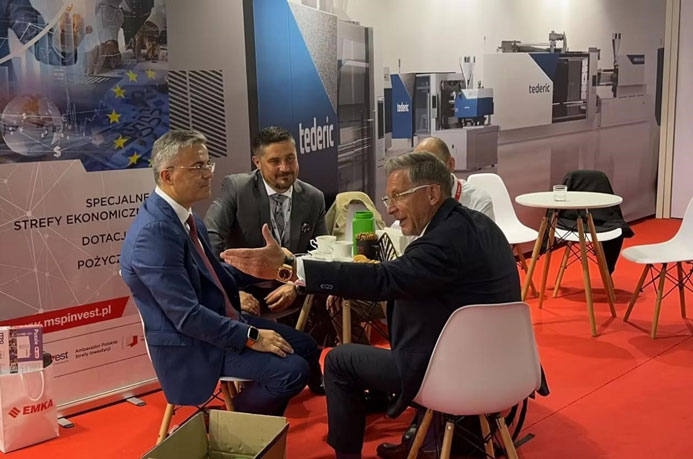

During the exhibition, Tederic's booth attracted numerous local Polish users for cooperation discussions. The constant stream of visitors stopping to inquire demonstrated Tederic's remarkable technical strength and market competitiveness.

Committed to enhancing product energy efficiency and exploring energy-saving and carbon reduction potential, Tederic's NEO·EII series has become the preferred choice for energy-efficient and carbon-reduction transformation equipment.

Moreover, to better meet the development trends in the thin-wall packaging field, Tederic's high-speed electric injection molding machines are adapted for multi-cavity thin-wall packaging products, featuring low energy consumption, high injection speed, and high precision.

This equipment boasts injection position repeatability of up to 0.01 millimeters, achieving 0.1% product weight repeatability, meeting the requirements for high pass rates and precise dimensions in thin-wall products. It also provides customers with overall solutions for low-energy in-mold labeling processes.

Additionally, the NEO·EII electric injection molding machine employs an advanced energy recovery system, saving an additional 8%-15% compared to traditional electric machines, with energy consumption levels meeting Euromap 9+ standards.

Note: For injection molding machines with clamping force less than 400 tons and idle power ≤1 kW or clamping force greater than 400 tons and idle power ≤3 kW, a plus ("+") should be added after the Euromap classification.

Tederic has consistently adhered to the path of independent innovation. Since entering the Polish market, Tederic has accurately grasped industry development trends and user needs. From the user's perspective, Tederic continually develops more flexible, diverse, and high-value-added plastic machine products and solutions, gradually securing a favorable position in the Polish market.